1st October 2018 --- To improve the energy efficiency of electric motors and industrial facilities in Singapore, the National Environment Agency (NEA) had introduced new requirements to align with the international standards. The single speed 3-phase induction motors sold in Singapore are required to register with NEA and meet the minimum energy level of IE3 (International Energy Efficiency Class 3).

Concurrently, Industrial Components and Equipment of Hitachi Asia Ltd., has proceeded to register the IE3 motors with NEA under Energy Conservation Act “MEPS”.

Features of Hitachi IE3 Motors:

1. Global standard

2. High-efficiency

3. Long motor life

4. Inverter operation is also available (1:10 or 1:20 constant torque)

5. Furthermore benefit

6. Operational cost saving

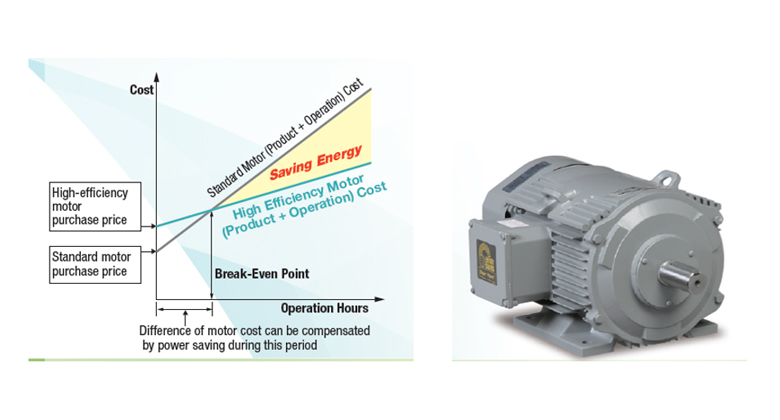

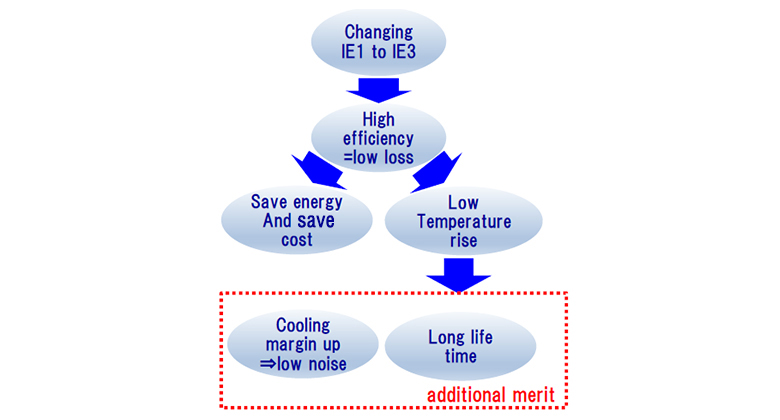

The advantage of Hitachi IE3 motor is very effective for electricity consumption reduction comparing to the standard motor. Hitachi IE3 motor loss is reduced 30~40% and we are able to get almost 5% energy saving if the motor is replaced from IE1 to IE3 thus save “energy cost”.

Most of the life cycle costs of the motor are electricity rate. The longer we used IE3 motor, the more we can save from electricity cost.

[Example]

Application: Facilities cooling-water pump

Motor: 45kW 4P (efficiency IE1: 90.2%, IE3: 95.1% at 50% load)

Condition: Load 50% driving time 8,160hr/year, energy ratio 14.3 JPY/kWh

Save cost: 153,233 JPY/year

Our product adapts to the following IE3 regulation:

| (EU) | High-efficiency regulation (commission regulation (EC) No.640/2009) |

|---|---|

| (China) | Minimum allowable values of energy efficiency and energy efficiency grades for small and medium 3-phase asynchronous motors (GB 18613-2012 class GB2) |

| (USA) | EISA (Energy Independence and Security Act) regulation |

| (Taiwan) | Chinese National Standards (CNS14400) |

| (USA) | EISA (Energy Independence and Security Act) regulation |

| (Singapore) | MEPS (Minimum Energy Performance Standards) |

Premium Efficiency1E3 Motor Complies with Singapore NEA’s MEPS of IE3