I am Inspired, I am Hitachi

Our work at Hitachi changes the world and makes our society a better place. Be inspired by how our colleagues are driven by the transformative nature of their work!

BE INSPIRED BY THE BEST OF BEST

Need inspiration for your IYGA entry? Check out the following outstanding IYGA projects from Southeast Asia!

Grand Prix Winner

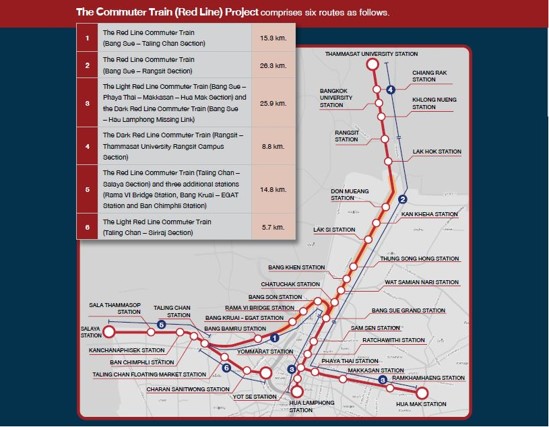

Title of Project: Improving Hitachi brand in Bangkok through the commencement of Red Line Operation in 2021

Hitachi Asia (Thailand) Co., Ltd.

Encouraged by Thai government to reduce air pollution that is caused by exhaust gas due to chronic and terrible traffic jam in central Bangkok area. This project will help expand business opportunities and strengthen the relationship between State Railway of Thailand (SRT) and Hitachi/HAS-TH since Hitachi has delivered diesel trains to SRT in 1933.

Success of Kasado's first export EMU (Electric Multiple Unit) to Thailand, and develop Hitachi's presence in Thailand This project has been introduced on YouTube Hitachi Brand Channel, and the movie has been watched over 843,000 times as of 22 June 2022 (https://www.youtube.com/watch?v=X05L3dtblAY). The success of Red Line Project is also a symbol of friendship between Thailand and Japan.

2nd Prize

Ready To Serve 200,000 Commuters Daily! Hitachi's First and Largest Single Order of elevators and escalators in Philippine Railway Business

Hitachi Elevator Philippines Corporation

The Philippine government is promoting a large-scale infrastructure development plan called "Build Build Build". The North-South Commuter Railway (NSCR) Project is an integral component of the said plan. The North-South Commuter Railway aims to improve and develop the railway system in the country, particularly, in the Metropolitan Manila area where rapid economic growth, traffic congestion and air pollution is on the rise.

As soon as the plans for this project was released and announced to the public, our Sales Engineers poured in their best efforts in attempt to acquire this prestigious project. The immensity of the project was undeniable, but the opportunity to contribute to a project for the Filipino people is what truly caught the attention of HEP. After long months of review and negotiation, HEP finally rejoiced upon being declared as the elevator and escalator supplier of choice for the North-South Commuter Railway Project. The order of 67 units of elevators and escalators for the development of NSCR Phase 1 was marked as Hitachi’s first and largest single order of elevators and escalators in the Philippine Railway Business. Phase 1 of the NSCR Project is a 38 km long railway line serving 7 stations that connects Malolos in the Province of Bulacan to Tutuban Manila. All the units are expected to be installed by May 2023.

The pursuit of this project has left a huge impact and opportunity to the members of HEP, with the chance to serve 200,000 commuters daily once it is fully operational. The privilege of providing the technology to ease the lives of a multitude of commuters is a colossal duty that HEP is excited to take head-on. In a metro as busy as Metro Manila, maintaining elevators and escalators to reliably serve thousands of commuters consistently with minimal breakdown is the responsibility that HEP is looking to showcase to the Filipino people.

HEP will continue to contribute to a sustainable society through providing safe, comfortable and the best elevators and escalators for the people and society.

3rd Prize

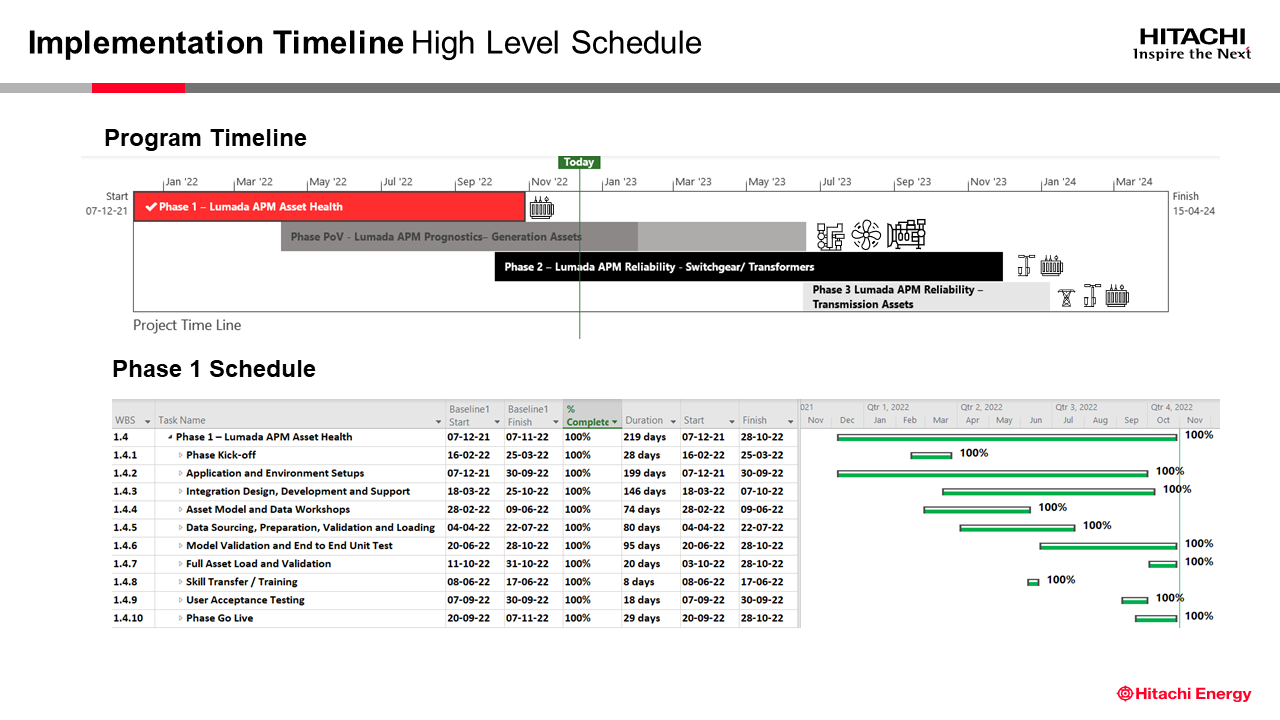

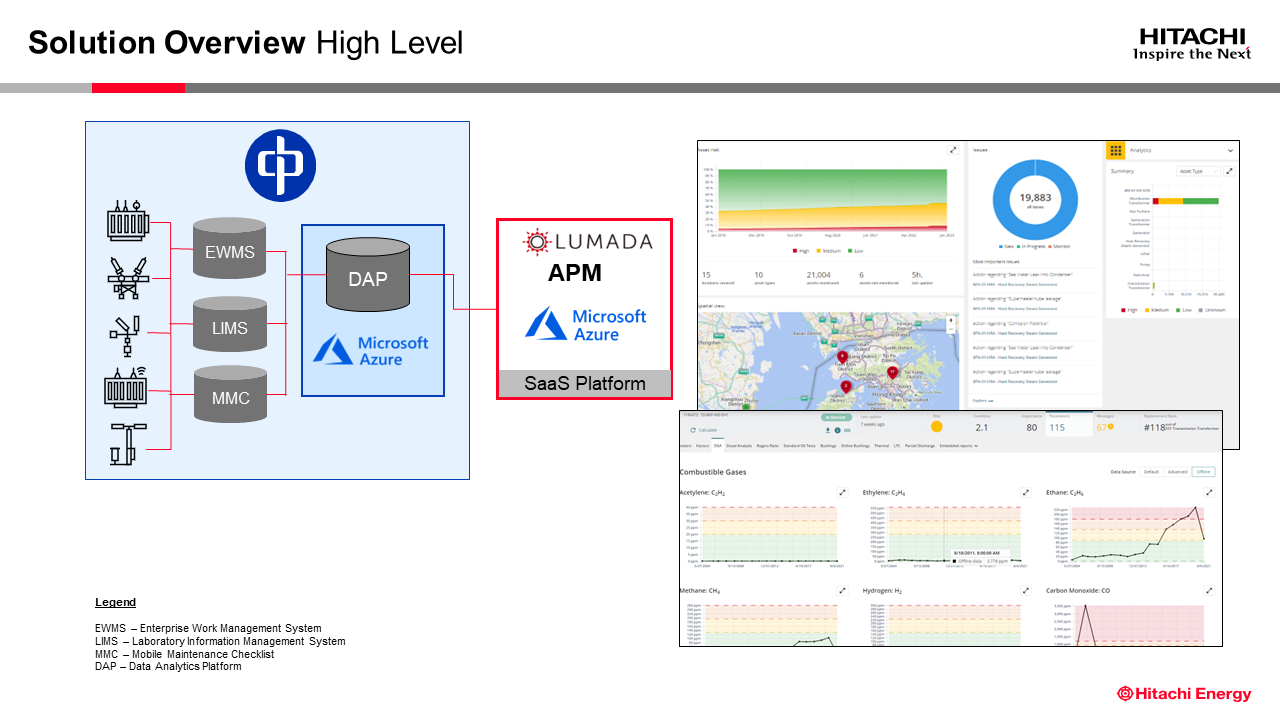

Digitizing electrical assets and predict the future!

Hitachi Energy Malaysia / Indonesia / Australia

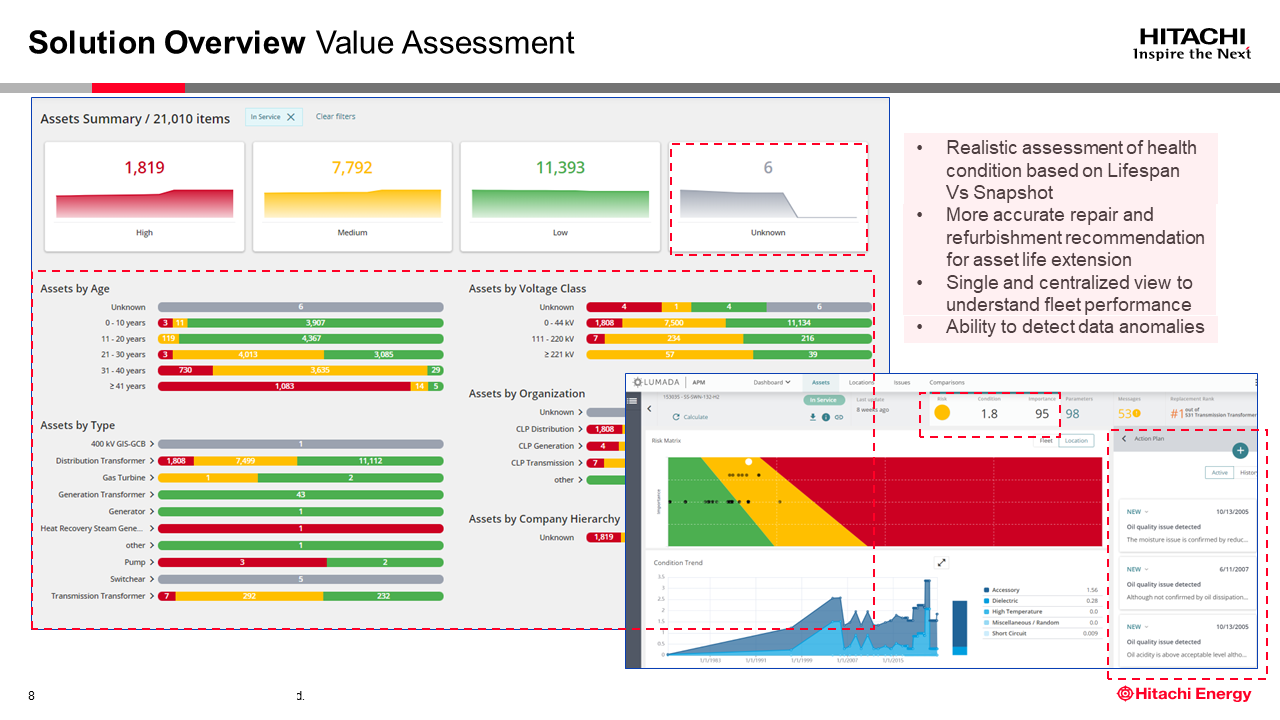

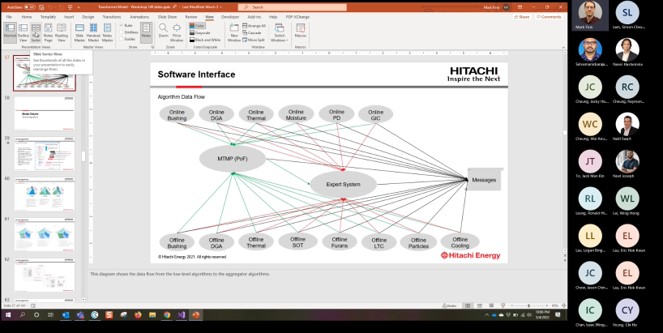

The Asset Health Management System (AHMS) project is deploying Hitachi Energy’s cloud based Lumada Asset Performance Management (APM) solution for China Light and Power (CLP), connecting digitally the data of ~20,000 transformers, ~60,000 switchgears, and ~25,000km of transmission lines and cables to a centralized system. CLP has one of the highest overall reliability rates in the industry (99.995%), and wishes to improve it further while reducing Operation and maintenance cost. Hitachi Energy's solution will help CLP towards this goal.

The AHMS project is currently being executed over three phases of implementation spanning two years, beginning January 2022. The solution will thereafter serve CLP for ten years of subscription period, helping CLP move from the traditional time-based maintenance philosophy to condition-based and predictive maintenance philosophy. It is an important step in CLP’s digital transformation journey, changing from paper-based processes to extensive use of modern digital technology integrating various systems via a cloud-based data lake.

Lumada APM’s advanced expert models and algorithms will help CLP identify assets in critical conditions before failure occurs, allowing CLP to “see the future” and act in advance to address the issues, thereby further strengthening CLP’s top-notch and industry leading performance in delivering electricity to its consumers reliably and efficiently.

Lumada APM also helps CLP decide which assets need repair and which need replacement, potentially extending useful lifespan of the assets, hence contributing to the environment by decreasing wastage.

The project will increase Hong Kong’s social and economic value by ensuring a reliable electricity supply network so that people’s QOL improves, and commercial/industrial activities can prosper.

Special Recognition Award

Breaking into the semiconductor industry with Panel‐level Format EFEM (Equipment Front End Module)

PSB Technologies Pte. Ltd. (JR Automation Singapore)

The race for the wafer fabrication plants to make their transitions to the next‐generation fan‐out technology using the panel‐level format has intensified as scaling up the packaging density at wafer-level has reached a bottleneck.

In panel‐level fan‐out packaging, a higher die density die on a panel can be achieved compared to when you use a traditional round wafer. At the same time, by implementing panel‐level packaging, the cost of fan‐out will also be lowered. While wafer‐level thin‐film technologies could be largely employed for panel‐level processing, panel handling is a new challenge for wafer fabrication plants in the midst of this transition. The development of the equipment front‐end module (EFEM) is a critical enabling technology that could help the wafer fabrication plants overcome this issue in panel‐level fan‐out manufacturing.

Despite our limited experience in wafer handling and no prior experience in SECS/GEM software development, we were invited by a global leading wafer fabrication plant to develop the EFEM for handling the next‐generation panel‐level substrates and glass carriers. Against stiff competition from existing leading wafer‐level equipment suppliers, we were selected to develop the panel EFEM together with two other leading wafer industry equipment suppliers.

In our first attempt, we successfully overcame the panel‐level handling challenges. Furthermore, with our ability to develop a full GEM300 compliant software as well as our attentiveness and responsiveness to the customer's unique requirements, we have been selected as a key EFEM supplier for the customer, providing JRA and Hitachi an inroad into new business opportunities in the semiconductor industry.

Sustainability Prize

Taking the First Step In Encouraging The Use of Solar Power Plant In East Karawang Industrial District

PT. Chemco Harapan Nusantara (Hitachi Astemo)

To promote the policies and programmers necessary for popularizing the applications of solar energy technologies in the Industrial area.

To create awareness about the uses of solar energy among automotive component Industries.

To promote green building design for efficient use of solar energy in Industrial area.

Sustainability Prize

Sustainable Carbon Neutral Society with Zero Investment by One-HITACHI Solar Power Generation Toward Net Zero Emission Society

Hitachi Asia (Thailand) Co., Ltd.

With the economic situation, and COVID19 pandemic, many business entities are facing difficulty and losing profits, including the National Energy Policy "Net Zero Emission" in Thailand, thus we, "HITACHI ASIA (THAILAND) COMPANY LIMITED” whom takes role as Project Leader and Management of this project, is collaborating with “MITSUBISHI HC CAPITAL (THAILAND) CO., LTD.” whom can provide financial services called "Power Purchase Agreement" to corporate customers, and “SANTEC POWER SOLUTIONS COMPANY LIMITED” (Joint venture Company of Hitachi Power Solutions Company Limited Japan) whom can provide Engineering services and maintenance works for power plant and industrial sectors, to create a "Solar Power Generation solution for Self-Consumption with Zero Investment Program” for HITACHI Group Companies and customers in Thailand in order to support customers to achieve cost reduction and improve CO2 emission toward Net Zero Emission society within the same program.

With this program, MITSUBISHI HC CAPITAL (THAILAND) CO., LTD. will provide a "Private Power Purchasing Agreement (PPA)" with 10 – 20 years contract period by investing and installing a solar power generation system including battery storage system on customers' rooftop without any cost to customers. As the result, MITSUBISHI HC CAPITAL (THAILAND) CO., LTD. will sell-back electricity from solar power production to the customers with the cheaper electricity fee than Electricity Authority of Thailand. Thus, the customers can achieve the electricity cost saving and CO2 emission reduction.

In term of the solar power generation system, it consists of many of HITACHI components such as Solar inverter (by Hitachi Hi-Rel India), Programable Logic Control, Circuit Breaker and etc. (by Hitachi Industrial Equipment System), and Battery Storage System (by Hitachi Energy Thailand) to ensure the customers on system reliability and efficiency. Furthermore, we are targeting to propose an expansion solution to solar power system with HITACHI Energy Management System in the next phase in order to support customers to achieve high efficiency of utility self consumption and CO2 emission reduction.

Innovation Prize

Demand Response Management System, Innovate IT on Sustainable Power for Thailand’s Bright Future.

Hitachi Asia (Thailand) Co., Ltd.

Thailand’s The Energy Policy and Planning Office (EPPO) has acknowledged plans to drive the implementation of the smart grid of the country in the short term (2017 – 2021), by the setting the framework for the development of smart grids which include Demand Response Management Systems. EPPO was assigned to the Ministry of Energy, Ministry of Interior, Energy Regulatory Commission (ERC). Electricity Generating Authority of Thailand (EGAT), Metropolitan Electricity Authority (MEA), Provincial Electricity Authority (PEA) and other related agencies to proceed on the development of the Smart Grid network according to the plan. Thai government has given importance to energy conservation to continuously reduce electricity consumption. Demand Response (DR) operation plays an important role in balancing power shortages, especially the shortage of natural gas fuels which is one of the main problems of the country during the past many years.

Around 2018, the agencies have started to plan the Demand Response more automated by Energy Management System (EMS) in order to be able to perform automatic Demand Response in Thailand through the Demand Response Control Center (DRCC) system, including to enable EGAT to prepare to order the Demand Response to the Electricity Seller Authority such as MEA and PEA. EGAT is therefore necessary to create a prototype project to demonstrate the Demand Response including the development of a DRCC. EGAT has worked together with Chulalongkorn University (CU) on this prototype project of Demand Response Management System (DRMS). This is when our team has started discussion with EGAT and CU supporting all technical information because Japan has already started the implementation of DRMS in Japan before Thailand. This is the start of our mission, we have laid out our plan to introduce Hitachi DRMS technology to Thailand. Working together with customers from the ground up; sharing technical information and plan for customer to consider in their project implementation. In 2021, when we actually won the bidding of the project and received contract worth JPY 65 Million at the end of April 2021 and completed our project implementation by December 2021 and maintenance service by December 2022 to end our Thailand’s mission.

Digital Prize

Improve people’s QoL and the Economy of Vietnam with Hitachi's C-ACM!

Hitachi Asia (Vietnam) Company Limited

While under the influence of COVID19, the economy remained stagnant in 2020, HASVN was seeking for a way to help recovering the economy in Vietnam. In 2021, after the business activities constraints by COVID19 begin to lessen, the consumer finance industry was also growing significantly, and the number of loan companies was increased to meet the financial needs of many people. HASVN has a Consumer Finance Client who thought that it was easy to approach people and let them get a loan for consuming. But unexpectedly it seemed that the number of applicants for loan did not increase so much. The main cause was the inefficient application process. Normally, loan contracts in Vietnam were still mostly paper-based, and the problem was that it took a lot of time to request for correction after reception, it also took time for identity verification. In addition, there was a problem that there were only a few places where people could apply for loan.

Therefore, Hitachi thought that if Hitachi can cooperate with other related partners to solve these problems, the number of loan application would be increased and as the result, Hitachi can contribute to improve microfinance field, and will help to circulate the economy in Vietnam. To realize this mission, Hitachi raised below 2 aims:

1. Hitachi helps people to easily access and apply for loans, then they can borrow money and increase their consumption amount.

2. Hitachi helps the Financial Company to get more loan applications and more revenue from these contracts. As a result, by using this revenue, the Financial Company can begin new business and contribute to society.

To do this, Hitachi will need to use our technology to solve the issues below:

i. Make loan application process more efficiently

ii. Make solutions to increase the number of places to apply for loan

To solve the above problems, Hitachi has proposed and received an order for the introduction of C-ACM from the client.

C-ACM is a solution that allows customers to use a tablet with Hitachi’s application installed, it can handle the process from beginning to completing loan application without a salesperson. Customer can apply while talking with the operator at remote center through video call, so operator can immediately confirm customer identity and company affiliation. The solution also means that everyone including the people who live in the countryside where there are few salespersons, like farmers and elder people and so on, can do loan application by themselves through C-ACM devices being placed all over Vietnam.

By using C-ACM as Hitachi's State-of-the-art IT technology, Hitachi achieved the mission we raised.

CSR Award

By planting mangrove trees, we reduce in abrasion on the seacoast, together bring back the smiles and hopes of the people of Muara Gembong

PT Hitachi Astemo Bekasi Powertrain Systems

The occurrence of coastal abrasion which caused the village of Muarajaya, Pantai mekar Village, Muara gembong, to begin to erode, this has been happening since 2009, it has been about 10 years. The once crowded village has begun to be deserted because its occupants left it due to damage to houses or public facilities in the village, we are here with all companies that care, to work together, contribute and become sponsors to carry out activities aimed at preventing further abrasion by means of plant a Mangrove Tree, in 2019.