Key Features

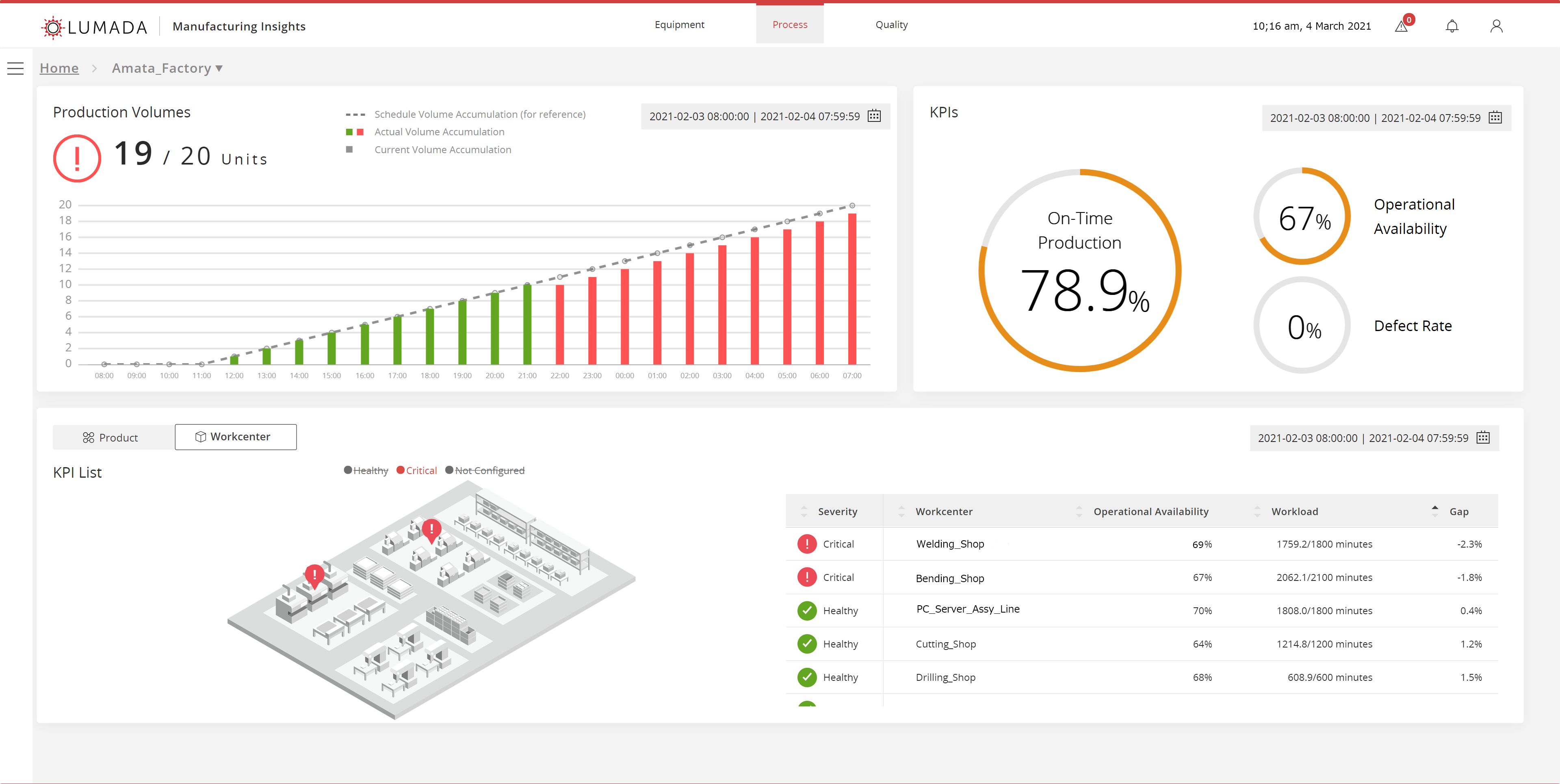

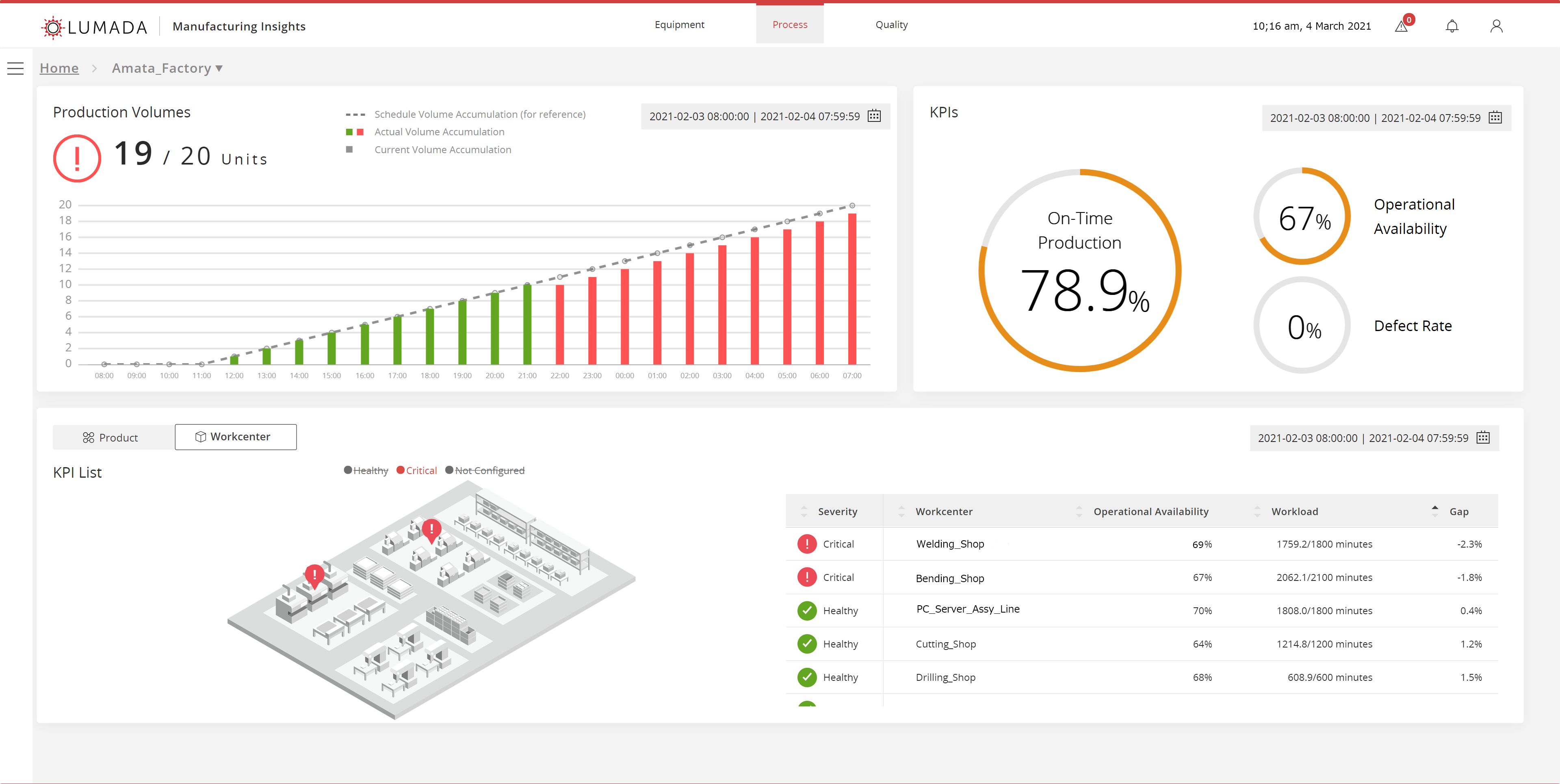

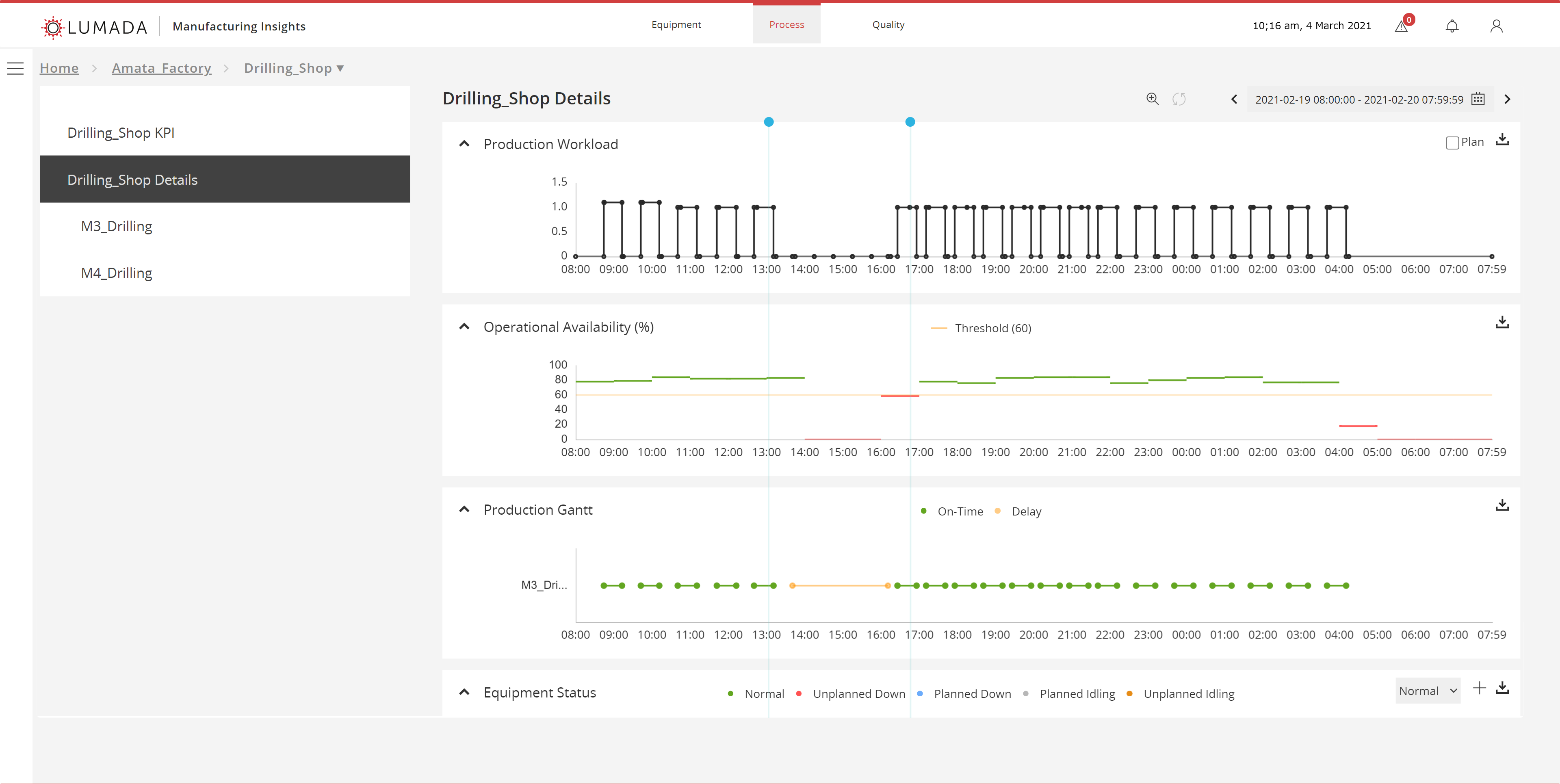

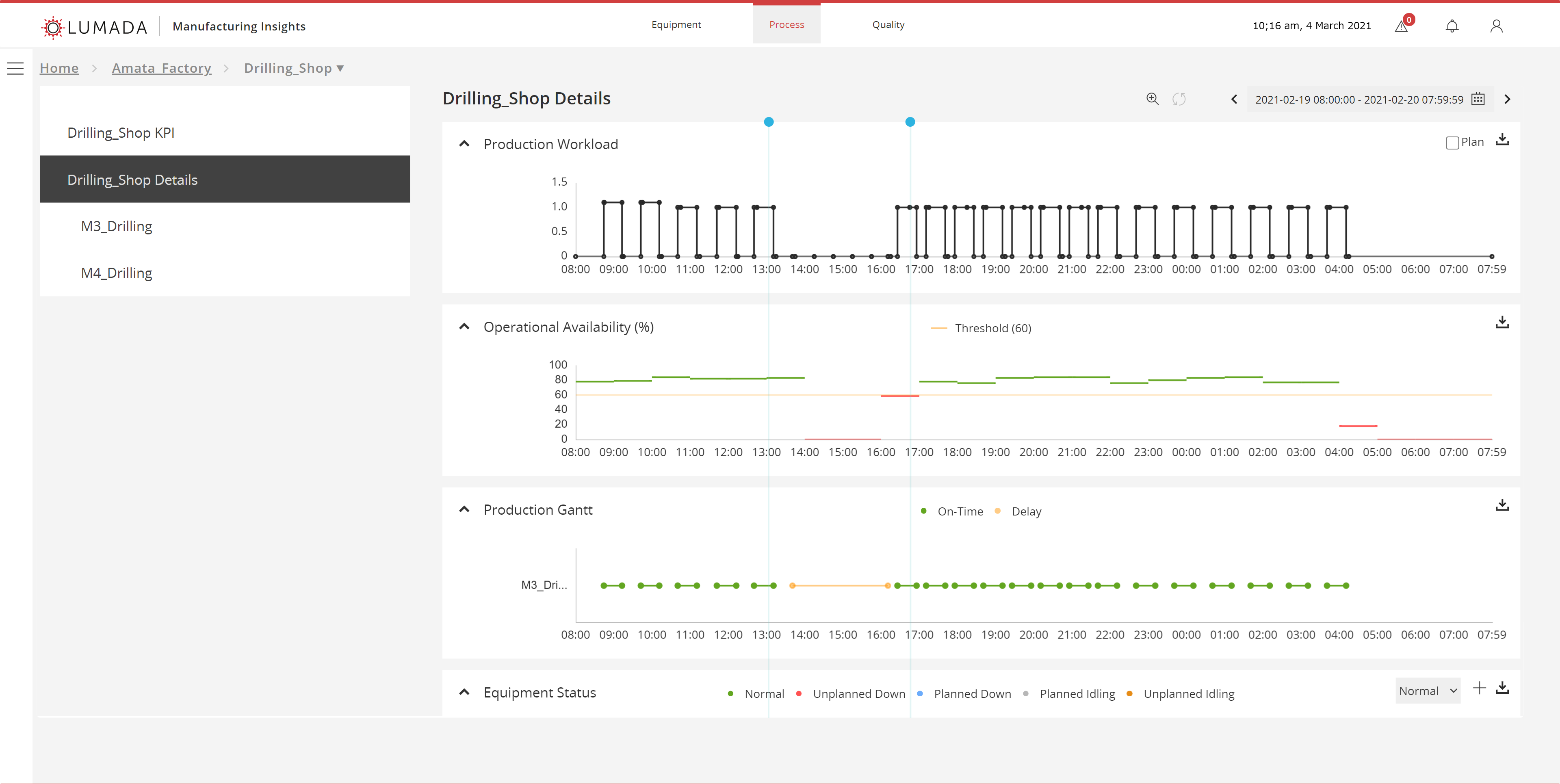

You can check KPI achievements and the progress of production at the factory or of a production line and verify whether they are operating normally

- Production volume Planned production amount and actual production amount

- Productivity On-time delivery rate, Operational availability, Defect rate

- Equipment operation rate OEE*, Time-based operation ratio, Performance efficiency,

Non-defective rate

* OEE: overall equipment effectiveness

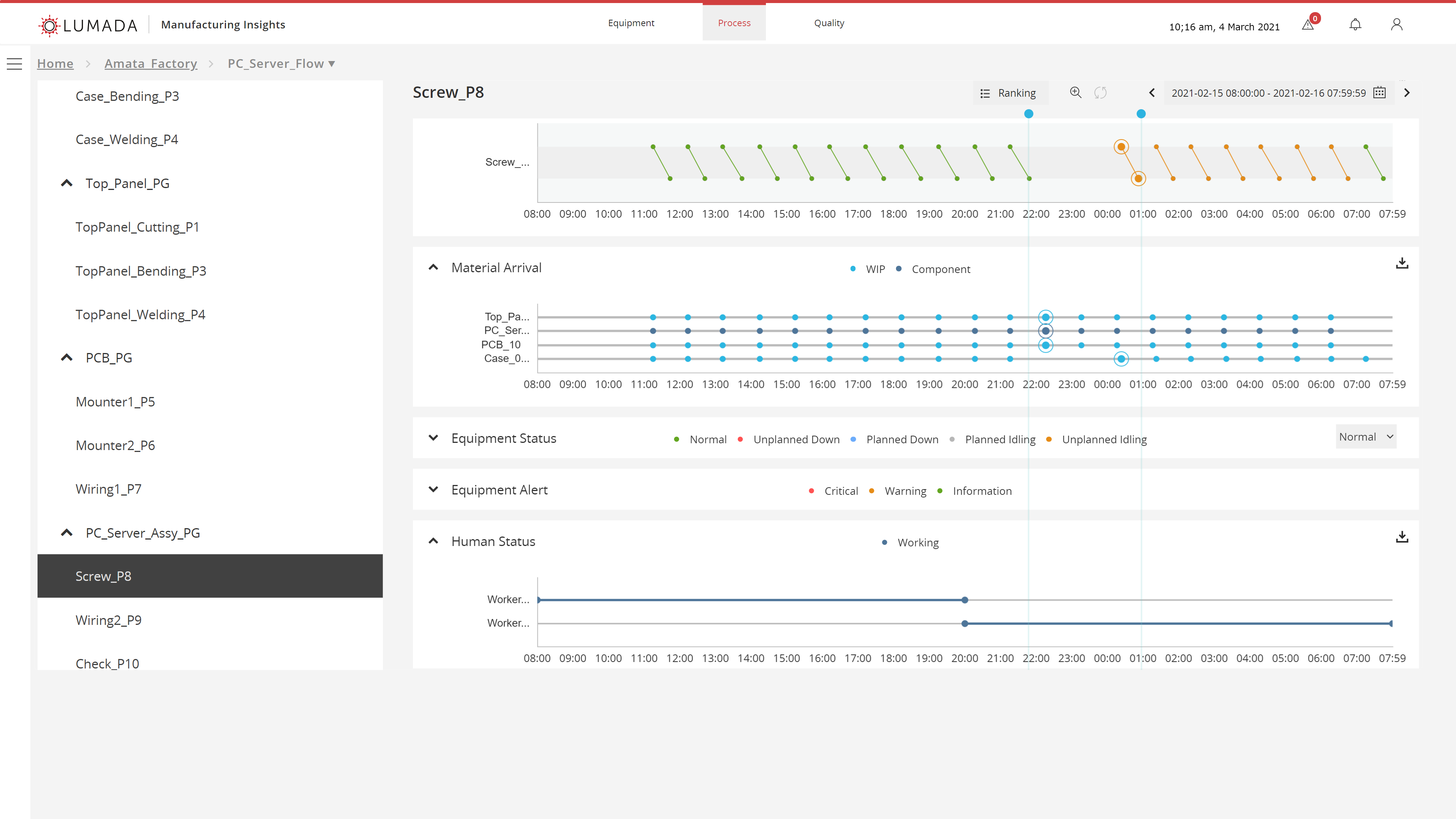

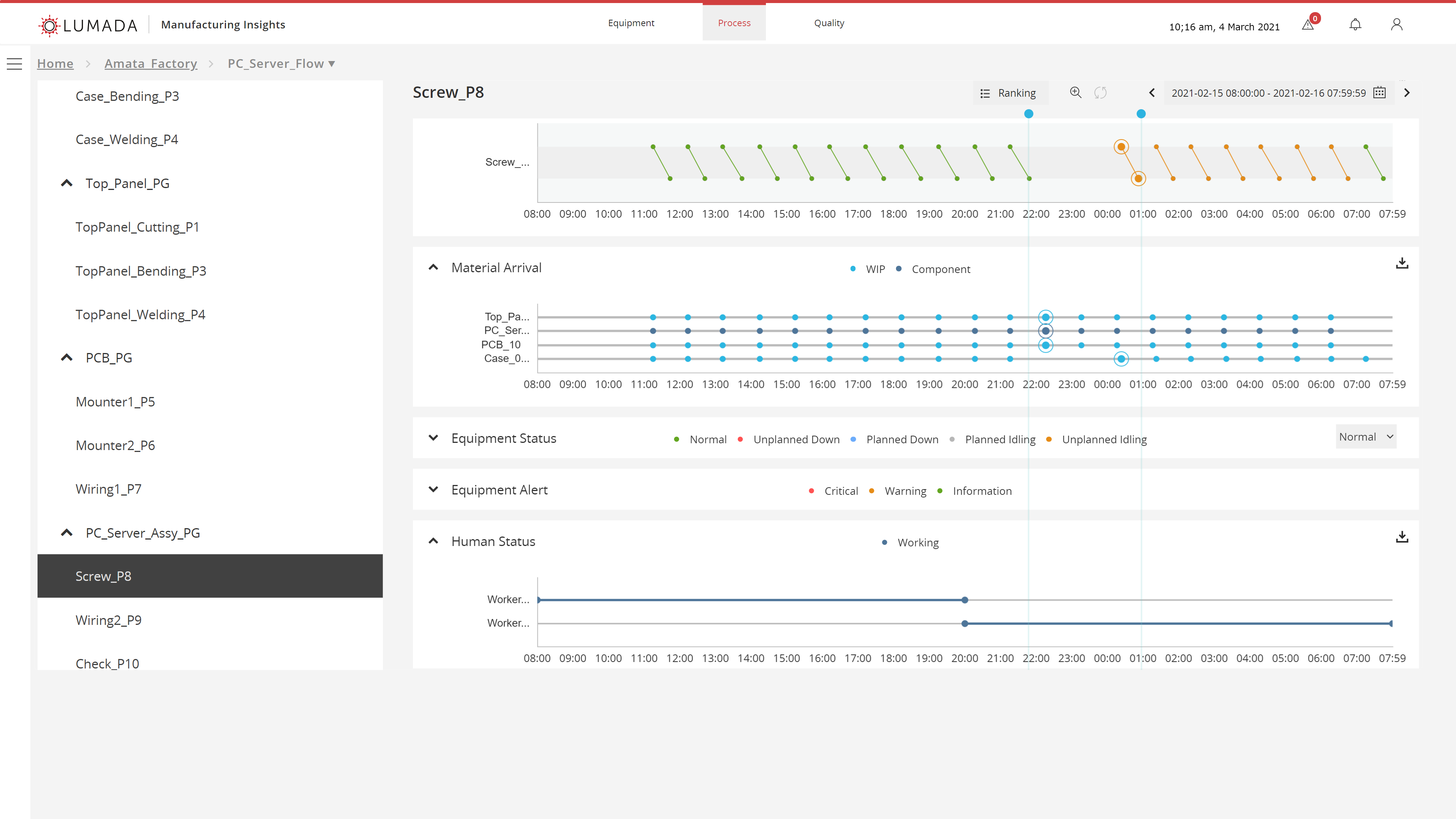

MfI performs 4M* analysis to provide visual information showing when, in which process, and under what conditions the productivity worsened. Based on the analysis of the balance of two adjacent processes or all the processes, you can identify the actual bottleneck and formulate a plan for kaizen measures for optimization. MfI also automates the collection and calculation of results data to facilitate the measurement of kaizen effects. * 4M: huMan, Machine, Material, Method

- Productivity

On-time delivery rate, Operational availability, Defect rate - Production status

Retention times for work-in-progress products and parts, Manufacturing lead times) - Production bottlenecks

Process start and end times, Status of workers, equipment, and members

MfI provides a centralized view of equipment operation statistics. You can confirm the current operation status and quickly identify the causes of any problem that occurs. Based on the accumulated operation data, you can also analyze the frequency and times of abrupt stoppages to formulate plans for maintenance and inspections.

- Equipment operation rate

OEE, Time-based operation ratio, Performance efficiency, Non-defective rate - Cycle time

Factors that contributed to equipment stoppages

Pareto chart, Equipment alert log - Sensor values